What is the fabric modal?

Beech tree pulp serves as the main component for producing modular fabric—semi-synthetic textile material. Rayon exists as a type of this fabric, which provides exceptional smoothness along with high softness and air permeability.

The production creates a fabric with a cotton-like texture that outperforms standard cotton when it comes to moisture absorption and breathability and comfort during wear.

Exploring the Different Types of Modal Fabric: Which One is Right for You?

People can adjust modal fabric by applying diverse customization techniques to produce solutions ranging from apparel to domestic textile items. The basic production component of modal fabric originates from wood pulp, yet its specific makeup depends on which processing techniques, along with material mixing techniques and finishing treatments apply to each product.

Standard Modal Fabric

Mattermill’s standard modal stands out as the basic form of modal textile because it combines breathability with moisture absorption while maintaining pleasant softness.

Best for everyday clothing, basic loungewear, and home textiles.

Feel: Soft, silky, and breathable.

Advantages: Affordable, widely available, and comfortable for regular wear.

MicroModal

Modal fabric comes in two variations, with MicroModal delivering lightweight and delicate characteristics compared to conventional modal clothing fabric. The fabric surpasses typical modal material with its extremely soft touch against the body.

Best for: Lingerie, intimate apparel, activewear, and premium fashion items.

MicroModal fabric provides an exceptional ultra-soft and silky feel, which creates a delicate fabric texture.

Advantages: Extra comfort, lightweight, and great stretchability.

EcoModal

The sustainable version of modal fabric goes by the name EcoModal. The manufacturing process of EcoModal requires less water and chemicals since it implements sustainable production practices. Brands interested in environmental responsibility present EcoModal fabrics because these materials originate from sustainable wood pulp and break down safely in the environment.

Modal Blends

The textile industry uses Modal as a standalone fabric as well as with combinations of other materials to improve its technical qualities. The most typical combinations among modal fibers consist of these three pairs:

The fiber combination of modal and cotton uses natural modal fiber properties to create a luxurious feel together with cotton’s air circulation and long-lasting nature. This blended product serves as the primary material for household textile items and regular apparel.

Tencel Modal Fabric

The Austrian textile company Lenzing AG manufactures Tencel Modal as their brand of modal fabric production. Tencel Modal undergoes sustainable manufacturing because the production techniques incorporate water and solvent recycling through a complete loop operation.

Best for: high-end fashion, sustainable clothing, and eco-conscious consumers.

The fabric reveals luxurious silk-like softness together with a smooth texture that gives a velvety touch.

- Advantages: sustainable production, high durability, and premium feel.

-

Organic Modal

Organic Modal fabric originates from cultivated beech trees that mainly use organic farming practices, which exclude any chemicals or pesticides. By using organic farming techniques during production, organic modal fabric becomes a better environmental choice than standard modal fabric

Advantages: No harmful chemicals, better for sensitive skin, and eco-friendly

Modal with Stretch

Modal fabric receives stretch functionality through a combination with either spandex or elastane added in trace amounts to enhance its stretchability. Such fabric blends enable the modal fabric to keep its delicate softness together with its new stretching capability.

- Best for: Activewear, leggings, and body-hugging garments.

- Feel: Soft, breathable, and stretchy.

- Advantages: Increased comfort, flexibility, and durability.

also read: Clothing Manufacturing Companies in Pakistan

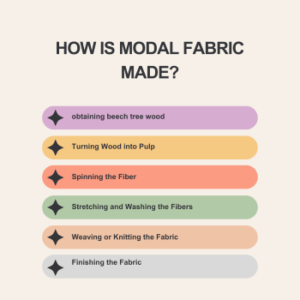

How Is Modal Fabric Made? A Step-by-Step Guide to Its

Creation

The production process of modal fabric creates a semi-synthetic textile from natural wood pulp, which results in a sophisticated, soft, and premium material. This guide provides an orderly description of the modal fabric manufacturing process:

-

The production of modal fabric starts with obtaining beech tree wood for its transformation into textile fibers.

The origin of modal fabric starts with acquiring raw materials, which will be used in the manufacturing process. Beech tree wood pulp forms the main material used to create Modal fabric while continuing to renew naturally. Beech trees develop rapidly in sustainably managed forests so their material continues to support environmental sustainability.

Turning Wood into Pulp

The harvesting of beech wood leads to the following process that turns it into wood pulp. Wood natural chips endure a chemical-based processing at sodium hydroxide level to generate its cellulose fibers from their broken structure. The wood pulp processing results in a voluminous mixture of fibers, which becomes the primary material for modal fabric production.

Sustainable advancements involve using sodium hydroxide and carbon disulfide chemicals less frequently because they are harmful to the environment.

The pulp undergoes solution dissolution into a chemical mixture.

Next, the wood pulp is dissolved in a chemical solution to create a viscous substance known as “viscose.” The viscose solution presents suspended cellulose fibers inside its liquid composition. At this moment in the modal production process, the method displays similarity with other rayon fabric manufacturing methods.

Spinning the Fiber

A spinneret features small holes that enable viscose solution to flow through in order to generate extended continuous fiber shapes. The viscose solution turns solid during fiber strand extrusion, much like the process of spinning thread formation. The production process includes washing the fibers until all chemicals from the viscose solution disappear completely.

Stretching and Washing the Fibers

The production process of fibers continues by stretching them because it extends their length and strengthens their overall structure. The fibers need a washing process with a neutralizing solution to treat impurities while extracting all residual chemicals. After washing, the modal fibers become ready for the following manufacturing phase because they have achieved smoothness.

Spinning the Fibers into Yarn

The fiber production moves to yarn-making after performing a washing process followed by neutralization procedures. The development of fabric yarn represents the starting material, which will become woven or knitted fabric.

The final fabric processing is dependent on how the yarn needs to be used for the end application. Modal yarn requires twisting when producers want a firmer texture, or they can leave it untwisted to achieve softness.

Weaving or Knitting the Fabric

The manufacturing process continues when ready yarn receives weaving or knitting procedures to produce fabric. The selection between weaving or knitting determines the fabric’s ending texture together with its stretching characteristics.

Woven modal fabrics present themselves with a smooth finish, whereas knitted modal fabrics demonstrate stretchy and flexible properties.

Finishing the Fabric

Woven or knitted fabrics undergo a sequence of finishing steps after their manufacturing process. Manufacturers use dyeing methods along with printing techniques and softener applications to update the texture of fabric.

Final Inspection and Quality Control

A complete quality check occurs on modal fabric before its distribution for garment or home textile purposes. The fabric passes quality control checks to prove it fulfills all criteria regarding softness and color protection and durability alongside its expected appearance.

Quality control checks identify the defects, which get resolved prior to the transportation of the fabric to manufacturers for production.

End Products

The modal fabric moves through its last operational phase to become finished products. The finished products derived from modal fabric include clothing items, which include t-shirts, dresses, and activewear combined with home textiles, including sheets, towels and blankets.

The Process Behind Modal Fabric: From Beech Trees to Softness

The production of modal fabric starts with beech trees since they are the basic materials used to create this premium textile. The conversion of beech wood into soft, breathable modal fabric follows a systematic process that produces each distinctive characteristic of the finished product.

Harvesting the Wood

Manufacturing begins by harvesting sustainably obtained beech trees. The chosen trees exist because of their plentiful presence and their quick growth rate. The forestry industry collects wood pulp from trees before starting the subsequent manufacturing process.

Pulping the Wood

After the beech wood harvest, the pulpification of wood occurs by using chemicals. A breakdown solution soaks the pulp material until wood fibers form. Treatment of natural cellulose wood transforms it into material which can later spin into yarn.

Spinning the Fibers

By using spinnerets that create thin holes, the cellulose fibers dissolve in their chemical solution until they become continuous filament-like structures. The dried fiber strands become solid while they are collected in spinning operations that turn them into yarn.

Weaving into Fabric

The fabric emerges after weaving or knitting finished modal yarn. The characteristic soft feel, along with the smooth texture of modal fabric, first develops at this point. The completion of fabric production reaches this point where further chemical processes will transform it into a refined product with an appealing appearance and extended lifespan.

Finishing Touches

Finally, in the production cycle of modal fabric, manufacturers apply treatments that boost its functioning capabilities. Modal fabric undergoes dyeing to achieve colorful appearance followed by finishing processes that add either softening or sheen attributes or moisture absorption benefits.

The textile industry values Modal fabric because it provides comfort and a fashionable appearance

Modal fabric steadily rose to fashion industry status because of its solid popularity. The blending of cotton gentleness with silk’s elegant touch within modal fabric results in an ideal comfort-versus-style combination.

Unmatched Softness

The fashion industry chose modal from among other fabrics because of its unbelievably gentle texture. The soft and velvety fabric feel against your skin makes it an ideal material for everyday clothes, which include t-shirts, dresses and intimate apparel products.

Is modal fabric breathable?

The high breathability of the modal enables thermoregulation for the body. The material provides excellent all-day usability because it works well for both everyday tasks and casual domestic activities. The fabric tends to wick away moisture to keep your body dry even during hot weather conditions.

Versatility in Design

Modal functions as an ideal fabric choice for multiple different types of fashion designs. Users can effortlessly implement modal into their wardrobe since it successfully matches many casual to chic styles through its adaptable range of products from loose dresses to lightweight activewear and warm jumpers to stretchable pants.

Durability with Style

Modal outlasts other typical soft materials such as cotton in terms of endurance. The material will not shrink during washing and will consistently keep its original style. Any fashion items created with modal keep their fresh and vibrant appearance throughout multiple wash cycles.

Understanding the Cost of Modal Fabric: Is It Worth the Price?

Modal fabric production cost bases on the expense of beech tree pulp that serves as its raw material. The conversion of wood pulp to fiber requires complex chemical processes that influence product expenses. Manufacturing modal fabric with its basic, cost-effective material becomes expensive because precise manufacturing requirements must be met.

Is Modal Worth the Price?

Products crafted with modal fabric remain durable because they resist shrinkage while continuing to serve consumers for extended periods compared to different textile materials. Because of its extended lifespan, Modal proves to be an excellent value through regular utilization for pajamas as well as sheets and activewear.

Modal Fabric and the Environment: Eco-Friendly or Not?

The market trend toward sustainable fashion and eco-friendly textiles encourages more people to choose modal fabric as their environmentally friendly substitute material.

The Raw Material: Beech Trees

The cellulose from beech tree wood becomes modal fabric through an extraction process of this renewable resource. Beech trees expand quickly through established, responsible forest management so sustainable forest regeneration occurs without resource exhaustion.

The Production Process

Making beech wood into modal fabric requires various chemical operations. The production process enables the wood to transition into fiber but necessitates the use of sodium hydroxide and carbon disulfide chemicals. The discarded use of these chemicals resulted in pollution together with waste accumulation. The industry progresses daily toward implementing more sustainable business operations.

Closed-Loop Systems

The production methods of major modal fabric manufacturers, such as Lenzing AG, now use closed-loop systems as an answer to environmental problems in traditional manufacturing. A closed-loop system collects wood pulp breakdown chemicals and then purifies them before their repeated use, which decreases waste and harmful emissions production.

Biodegradability

Modal fabric stands out because it has the distinctive characteristic of decomposing naturally over time. Natural decomposition happens to the modal fabric once discarded, whereas synthetic materials like polyester and nylon need hundreds of years to break down, so modal represents a superior green option during its end-of-life phase.

EcoModal and Sustainability

EcoModal represents modal’s improved variant that extends its capability to minimize environmental impact on a greater extent. EcoModal serves the market through a green production system that performs manufacturing operations with little water and minimal chemical substances.

Eco-modern brands depend on eco-modal traits to introduce an environmentally friendly fabric solution to existing textile options. EcoModal provides the modal fabric with superior sustainability features because it decreases the production of chemicals and waste outputs.

FAQs

2 thoughts on “Modal Fabric Explained: types, Benefits, Uses, and produced”