Introduction

First of all, in the Chiton garment factory, any object that can be used for wear, such as a T-shirt, sweater, pants, etc., is part of the apparel industry. Garments can also be used for different purposes, such as cut resistance or fire resistance.

Hats, shoes, and socks are also included in the apparel industry. The Chiton garment factory is diverse. Along with textiles, it is the biggest and oldest industry, providing employment opportunities worldwide.

The Chiton garment manufacturing sector offers worldwide services. The textile industry increased the country’s growth rate and economy. It involves different steps, such as converting raw materials into wearable garments. The growth rates of most countries depend on these industries.

Different departments in the garment industry

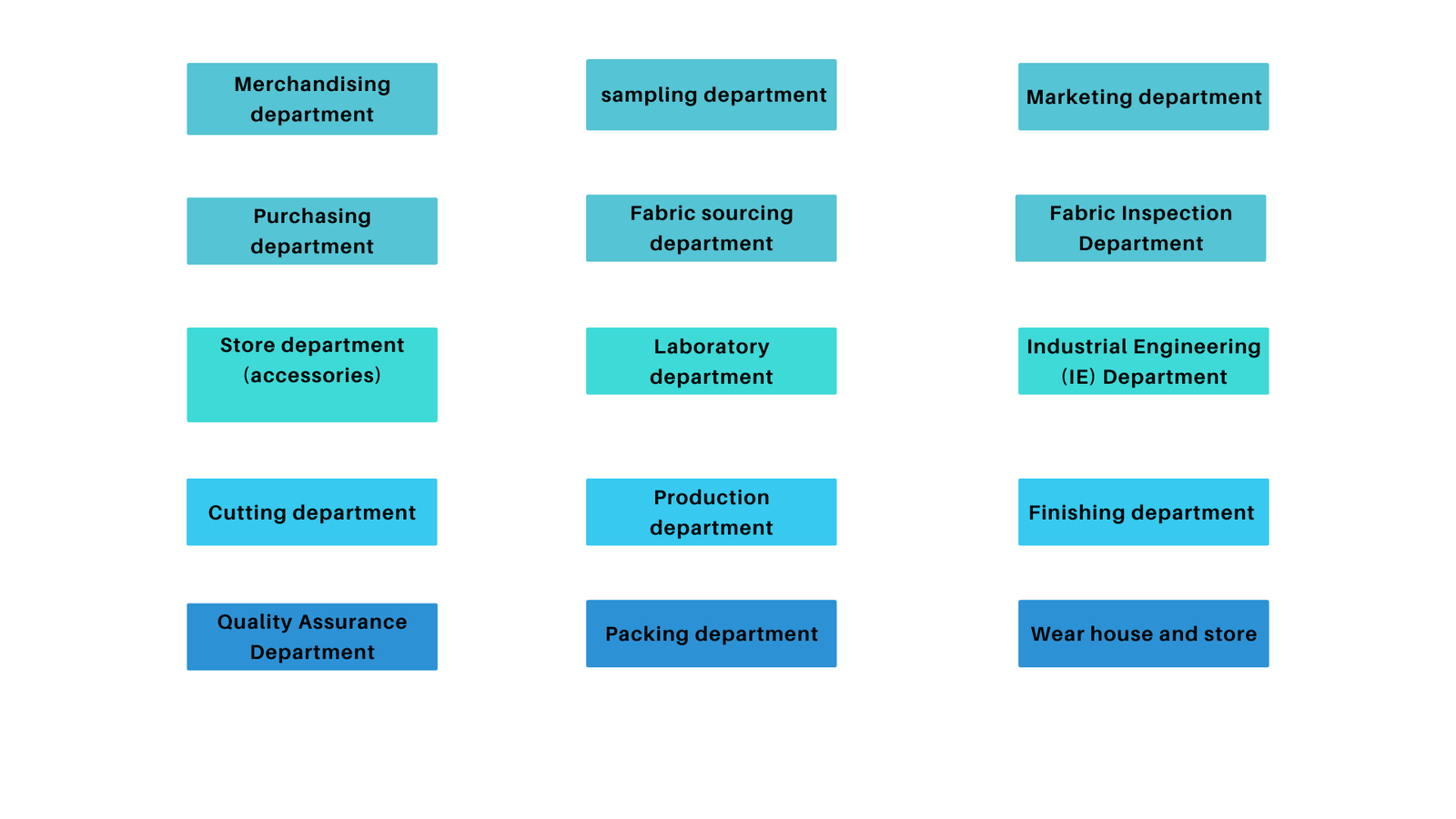

The clothing or garment industry consists of different departments. Every department is responsible for better production and producing high-quality products. There are different departments working in the textile industry, such as HR, finance, marketing, production, etc.

Discuss the different departments in the Chiton garment industry, such as

- Merchandising department

- sampling department

- Marketing department

- Purchasing department

- Fabric sourcing department

- Fabric Inspection Department

- Store department (accessories)

- Laboratory department

- Industrial Engineering (IE) Department

- Cutting department

- Production department

- Finishing department

- Quality Assurance Department

- Packing department

- Wear house and store

Responsibility of the different departments in the textile garment industry

Every department is responsible for its own task. The activities of all departments in the garment industry, as briefly explained below,.

Merchandising Department

The merchandising department is vital, because it is responsible for dispatching and executing orders (products). The merchandising department guides the processing of an order, from buying an order to completing the order.

The main objectives of merchandising are direct contact with the buyer and taking an order. After taking an order, source all the raw materials and start the production process, starting according to the plan.

order is carried out in the respective unit. The unit manager starts the production process and is responsible for producing a product of high quality.

Sampling department

The sampling department is directly in contact with the merchandising and production departments. The sampling department produced a single product from the production department

And obtained approval from the merchandise department to produce it in bulk quantity. It also determines the fabric conceptions, threads, and other accessories used.

Marketing department

The marketing department promotes and sells finished products to customers, retailers, and wholesalers. Marketers develop up-to-date marketing strategies. And manages all activities, such as advertising campaigns and the online store.

A marketer understands customer needs and wants. And design a marketing strategy that is customer-driven. A good marketer has good communication skills and a sense of humour.

Purchasing department

The sourcing department is responsible for sourcing the fabric and yarn. The purchasing department is responsible for purchasing all the raw materials and accessories used for production—materials used for making a product for which the department provides all the raw materials.

Fabric sourcing department

The sourcing department is responsible for delivering the order on time and with quality. That department will also be responsible for sourcing all raw materials, such as yarn, zippers, buttons, accessories, etc.

Printing Department

The printing process starts when the inspection of the fabric is completed. When the fabric is ready, send it direct to garment printing department. The printing process is done by the digital printing process.

Fabric Inspection Department

The fabric inspection team analyzed all the fabric and identified fabric cuts and hem of his garment. The inspection team does this using the given method. fabric selection by accepting the quality level (AQL).

How to design a Chiton garment store department (accessories)

That department plays an important role in production; all the accessories are available in this department—necessary items, such as cartons, collapsible garment hanger, poly bags, care label hangers, and other important items.

The laboratory department

Tests the fabric, accessories, and other instruments in a test center or lab, which will also be available in the company. test laboratory made on the demand of the buyer. Fabric color printing, washing, and other tests will also be checked in the laboratory center.

Also read: garment branding

Industrial Engineering (IE) Department

The department is responsible for cost control and production planning. All the production processes were analyzed, and there was an easy way to produce garments.

The industrial engineering department also determines whether the production process runs smoothly.

Cutting department

The production department gives the order to the cutting section and also provides the cutting sheet to the manager. That sheet mentions all the planning. Such as;

- Pattern maker

- cutting sheet

- garment design

- specs sheet

- sampling

- size ratio and colors of garments

Production department

When the cutting process is complete, garments are sent to the production unit. A production sheet will also be provided to the manager of the stitching unit, how to design a garment production unit. where all the production criteria are mentioned:

- Purchased Order Number (PO)

- Style of the garment

- The number of machine operators required

- Per-day production planning

- Required machine

Finishing department

The production department sends the product to the final inspection department. First of all, the end-line checker checks the piece of the garment and removes extra thread and fabric from the garment.

After completing this final inspection, the inspector checks and identifies defects and damages to the piece, alters and stains, and damages the fabric. The super final inspector will check these pieces again and send them to the quality assurance area.

Quality Assurance Department

Maintain the quality of the garment order. The QA department checks the piece in a few quantities and audits it. The QA department is responsible for the stitching audit and final inspection sections. Before shipping, the order quality of the garments will be 100% excellent.

Packing department

The packaging of the garments starts when the QA department completes its audit. The packaging department starts packaging all the accessories used in the garment.

The packing plan is provided to the packing manager. When the process is complete, send a carton of pieces to the warehouse. and ready for shipment.

warehouse and store

It is the department where all the finished products are collected and stored. The warehouse team managed all the pieces of the carton. Corton is loaded into the container and sent to the customer’s address.

conclusion:-

Garment factories have different departments that help gather and work hard to produce a product according to the customer’s needs and wants.

There are different departments, such as HR, finance, production quality, information technology, etc.

Every department in the chiton garment factory completes its task, which is provided to the seniors, and builds strong relationships with the workers and management. Some departments are service departments, and others are part of production.